Fromagex Products

From cultures to packaging, including equipment, here is our range of products.

MICROLANT® Classic 750 coagulant (5 gal)

HANNILASE® XP 750 is a microbial coagulant, mucorpepsin, produced by submerged fermentation on a vegetable substrate with a select strain of the fungus Rhizomucor miehei kept under contained conditions and not present in the final product.

The product contains milk-clotting enzymes which are active on kappa-casein, resulting in curd formation.

It is widely used in the cheese industry as an alternative to bovine/calf rennet and Fermentation Produced Chymosin (FPC).

The high unspecific proteolitic activity of Rhizomucor miehei has significant influence on yield, flavor and texture development of cheeses compared to calf- and fermentation-produced chymosin.

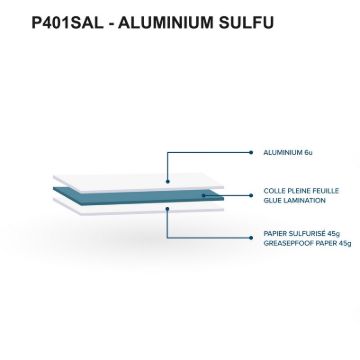

Aluminium Sulfu

Aluminum-based structure with a laminated sulfurized paper.

This material is a good solution for products needing low oxygen levels and some moisture absorption.

Well suited for artisanal butter thanks to its light-barrier spec.

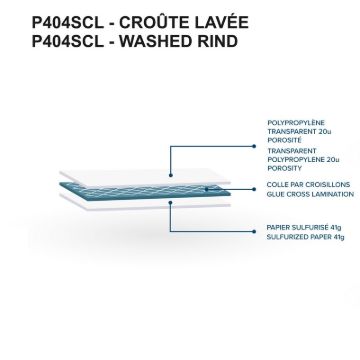

Washed Rind

Multi-layer packaging with a sulfurized paper and a clear polypropylene layer.

A patented Alize porosity treatment is allowing a homogeneous permeability.

Suits well to washed rind cheeses.

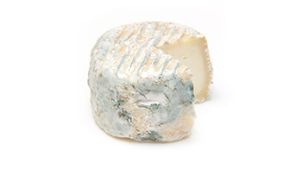

White Mould

Multi-layer packaging with a waxed paper and a white polypropylene layer.

A patented Alize porosity treatment is allowing a homogeneous permeability.

Suits well to bloomy rind cheeses.

Matrix Mono

Paper-based monolayer packaging with limited permeability.

Patented Matrix extrusion that regulates gas exchanges to control the cheese evolution.

Sealable structure made with 70% paper is designed to be recyclable.

Paputyl - Neutral

Paper-based structure with a laminated polyethylene inner layer.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

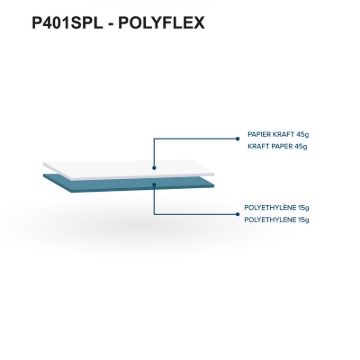

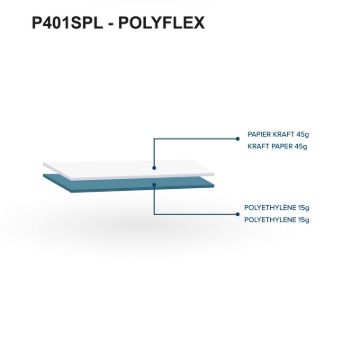

Polyflex - Neutral

Paper-based structure with a polyethylene inner layer for sealability.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

Polyflex - Custom (1 to 4 colors)

Paper-based structure with a polyethylene inner layer for sealability.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

Crystal 2.0

Multi-layer packaging with a translucent paper and a clear polypropylene layer.

A patented Alize porosity treatment is allowing a homogeneous permeability.

Heat-sealable.

Polyflex in roll

Paper-based structure with a polyethylene inner layer for sealability.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

Polyflex - Limited edition

Paper-based structure with a polyethylene inner layer for sealability.

Ideal for cut and wrap application for cheese shops and for whole wheel transport of aged cheeses.

Base on wheels for ripening rack 780 x 560 mm

Ripening mat straw type 69 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Stainless Steel Aging Racks 780 x 560 mm, 44 wires, H150/120 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Stainless Steel Aging Racks 780 x 560 mm, 44 wires, H115/85 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Ripening rack 630 x 510 mm, 31 wires, H85/55 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Ripening mat diagonal 50 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Stainless Steel Aging Racks 850 x 510 mm, 25 wires, H130/100 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.