Fromagex Products

From cultures to packaging, including equipment, here is our range of products.

CC-02 Frozen 500 u

Mesophilic homofermentative culture, type O.

This culture contains specially selected strains chosen for their phage resistance and ability to produce lactic acid quickly.

This culture does not produce CO2.

NOLA™ Fit 5500 Lactase, 1 L

NOLA™ Fit 5500 is a novel highly-purified and standardized liquid wide spectrum Bifidobacterium bifidum ß-galactosidase (lactase).

It is produced by submerged fermentation on a vegetable substrate using a selected strain of Bacillus licheniformis kept under contained conditions and not present in the final product.

The product hydrolyses lactose to a mixture of glucose and galactose.

The product is a premium lactase particularly suitable for fermented milks and cheese manufacture and to avoid off-flavor typically associated with lactose free UHT/ESL milk products.

CR-BOUQUET 01 Frozen 500 u

A defined adjunct culture blend which enhances the overall flavor intensity of the cheese by accentuating important flavor notes.

It enhances the balanced, mellow, rounded and clean flavors and suppresses unwanted flavors like sour, bitter and flat.

The culture contains a nisin producing strain for promotion of bacteria lysis.

Plastic aging rack 745 x 505 mm, H210/180 mm

Robust rack adapted to heavy loads

Plastic racks are light and sturdy, suitable for pressed cheese.

Our plastic aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack height should be done according to the cheese size.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for semi-hard to hard cheeses and blue cheeses.

Made in injected food-grade polypropylene, they are heavy duty and can be stack with a lot of weight on at more than 2 meters.

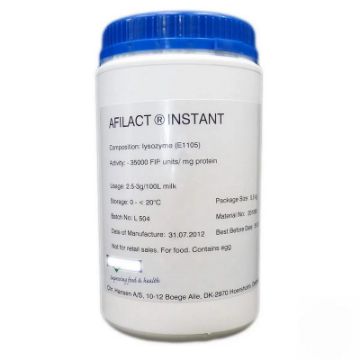

BB-12 Frozen 250 g (Probiotic)

Thermophilic lactic acid culture.

The culture is a defined single strain with a long history of safe use.

Substantial clinical documentation on possible health benefits are avaliable upon request and likewise are certificates of identification and certificates of safety and origin.

BB-12® is a registred trademark of Chr.Hansen.

Plastic aging rack 745 x 505 mm, H150/130 mm

Robust rack adapted to heavy loads

Plastic racks are light and sturdy, suitable for pressed cheese.

Our plastic aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack height should be done according to the cheese size.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for semi-hard to hard cheeses and blue cheeses.

Made in injected food-grade polypropylene, they are heavy duty and can be stack with a lot of weight on at more than 2 meters.

DVS-850 Congelé 500u

This Chr. Hansen DVS® culture contains defined mesophilic strains and is for continuous direct vat set use.

Ripening mat medium 50 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat square mesh 1 m x 20 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

Ripening mat straw type 69 cm x 25 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.

RST-632 Frozen 500 u

This Chr.Hansen DVS® culture contains defined mesophilic and thermophilic strains and is for continous direct vat set use.

The culture provides fast lactic acid production and high phage robustness without any CO2 production (homofermentative).

The culture is primarily applied in the production of semi-hard, hard and very hard pressed cheeses with a closed texture and a min cooking temperature at 35°C (95°F).

Examples of applications are Cheddar, Cheshire, Colby, Monterey Jack, Munster, Fontal, Raclette & Saint Paulin.

RST-643 Frozen 500 u

This Chr.Hansen DVS® culture contains defined mesophilic and thermophilic strains and is for continous direct vat set use.

The culture provides fast lactic acid production and high phage robustness without any CO2 production (homofermentative).

The culture is primarily applied in the production of semi-hard, hard and very hard pressed cheeses with a closed texture and a min cooking temperature at 35°C (95°F).

Examples of applications are Cheddar, Cheshire, Colby, Monterey Jack, Munster, Fontal, Raclette & Saint Paulin.

CR-213 Frozen 200 u

A defined blend of mesophilic homofermentative adjunct culture.

The selection of the culture is based on a unique balanced aminopeptidase composition.

The strains are all isolated from traditionally well known cheese cultures on the criteria that they have no or reduced capability to ferment lactose.

The culture is primarily applied in the production of cheeses where normally mesophilic lactic acid bacteria are used.

This culture is particularly used in Cheddar, Continental cheeses (rindless cheese), low-fat cheese and cheese containing vegetable fat.

The culture enhances the overall flavor intensity of cheese by accentuating all important flavor notes.

It enhances balanced, mellow, rounded and clean flavors and suppresses unwanted flavors such as sour, bitter and flat.

Stainless steel aging rack 630 x 510 mm, 25 wires

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

EMFOUR Frozen 500 u

Thermophilic homofermentative culture blend.

In 1984 it was selected by Dutch cheesemakers as the most effective thermophilic culture for accelerating ripening in Dutch cheeses.

The culture significantly enhances mature and nutty flavor notes, and there is a tendency towards sweet, sour and salt tastes, too.

The body of the cheese is also enhanced by the use of EMFOUR.

The culture can reduce the ripening time by several weeks depending on the type of cheese, storage temperature and desired flavor.

CR-MATURE 01 Frozen 500 u

A defined adjunct culture blend which enhances the overall flavor intensity of the cheese by accentuating important flavor notes.

It enhances the balanced, mellow, rounded and clean flavors and suppresses unwanted flavors like sour, bitter and flat.

The culture contains a nisin producing strain for promotion of bacteria lysis.

Some strains are facultative heterofermentative and may produce CO2 in specific conditions.

FLORA-DANICA Frozen 500 u

Mesophilic aromatic culture, type LD.

The culture produces flavor and CO2.

The culture is primarily used in the manufacture of Continental cheese types (Gouda, Edam, Leerdam, Samsoe) and soft cheese types (Lactic cheeses, Camembert, Blue cheese).

RST-633 Frozen 500 u

This Chr.Hansen DVS® culture contains defined mesophilic and thermophilic strains and is for continous direct vat set use.

The culture provides fast lactic acid production and high phage robustness without any CO2 production (homofermentative).

The culture is primarily applied in the production of semi-hard, hard and very hard pressed cheeses with a closed texture and a min cooking temperature at 35°C (95°F).

Examples of applications are Cheddar, Cheshire, Colby, Monterey Jack, Munster, Fontal, Raclette & Saint Paulin.

CR-520 Frozen 475 u

A defined adjunct culture blend which enhances the overall flavor intensity of the cheese by accentuating important flavor notes.

It enhances the balanced, mellow, rounded and clean flavors and suppresses unwanted flavors like sour, bitter and flat.

The culture is primarily applied in the production of cheeses where normally mesophilic lactic acid bacteria are used.

This culture is particularly used in Cheddar, Continental cheeses (rindless cheese), low-fat cheese and cheese containing vegetable fat.

Ripening mat large mesh 1 m x 20 m

Mats for covering racks

Covering racks with mats helps minimize the marking of delicate cheeses.