My account

Search

Fromagex

From cultures to packaging, including equipment, here is our range of products.

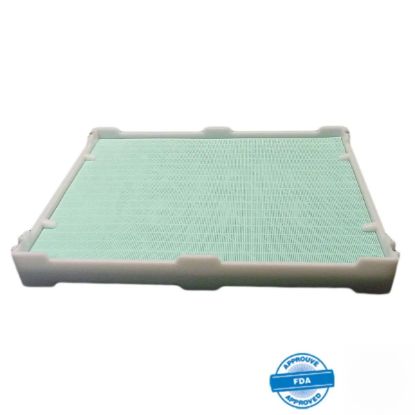

M604MMA0355

Rectangular microperforated mould 360 x 280 mm

Made in food-grade microperforated polypropylene and/or polyethylene.

Design according to 3A standards.

Perforation diameter from 0.5 to 0.7mm.

Made by injection of a single piece, no welding or assembly.

Standard grooving pattern or customized.

Call for pricing

Refine